An effective way to minimize the risk of costly repairs caused by pressure shocks.

Pressure surges are behind many problems in pipe systems, something that can be costly both financially and environmentally. It can cause pipe breaks, damage to valves, pumps, measuring equipment, couplings and suspensions. Examples of when pressure surges can occur are when the speed of the flow changes, pumps that start/stop too quickly, valves that open/close too quickly, air pockets in the pipe system and power outages.

The pressure shocks shorten the life of the various parts in the pipe system, which leads to increased maintenance costs. Regardless of the cause of damage and wear and tear, BPS can offer the right products and, above all, the expertise to help you avoid pressure strokes.

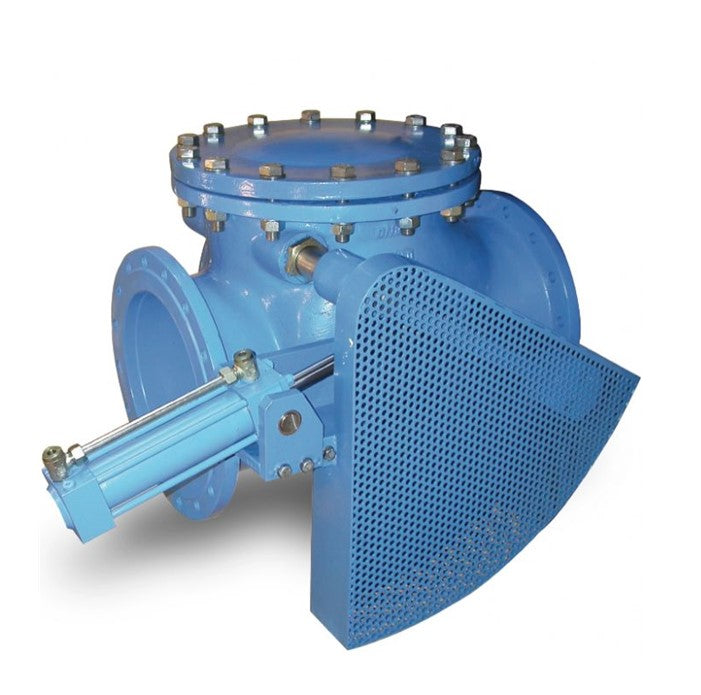

WHP non-return valve dampens pressure surges and increases the service life of pipe systems.

The WHP is a flap check valve that is equipped with an adjustable relief valve that evacuates excess pressure in the event of a pressure stroke. The valve also has a vacuum valve that opens at a negative pressure of 0.03 bar and lets in air during the negative pressure phase of the pressure stroke.

The overflow valve can also be used to facilitate emptying of the pressure line together with the relief unit. The valve is intended for water and waste water. The housing has an angled seat for best tightness at low differential pressures. The valve is made of steel that is vulcanized in NBR rubber. The flap is reversible. The valve has

full flow and very low pressure drop. The valve is equipped with a relief mechanism, which enables evacuation of the media on the pressure side in connection with service. Flanged connection, PN 10/16.

Increased durability

-A unique flap check valve with the option of adding a bypass that dampens pressure surges.

-Handles both over and under pressure.

-Reduces or eliminates pressure strokes.

-Reduces the number of pipe breaks in the pipe system.

-After prolonged use, the valve should be replaced. Checking the function of the overpressure valve and the vacuum valve should be done regularly.

- The right to technical changes is reserved.

-Increases the lifespan of all pipe systems.

-Easy to assemble.

-Low energy losses.

-Can replace hydraulic damping check valves.

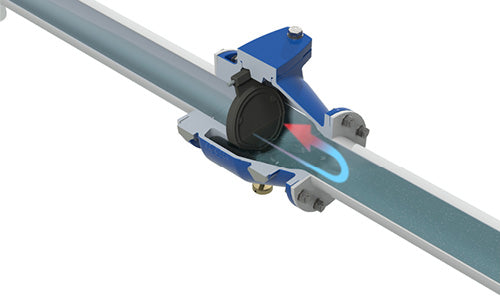

Without Water Hammer Protector

When the pump is switched off, the medium continues forward, this creates a negative pressure. When the liquid column then strikes back with full force, an overpressure is formed. This can cause severe pressure shocks.

With Water Hammer Protector

When negative pressure occurs, the vacuum valve lets in air. The air acts as an air cushion when the liquid column rebounds and dampens the pressure stroke.

If the excess pressure from the liquid column becomes too high, the overflow valve opens and allows the medium to pass past the valve into the pump.