WHP - a pressure shock dampening check valve

Use this text to share information about your brand with your customers.

Describe a product, share announcements, or welcome customers to your store.

Background & challenges

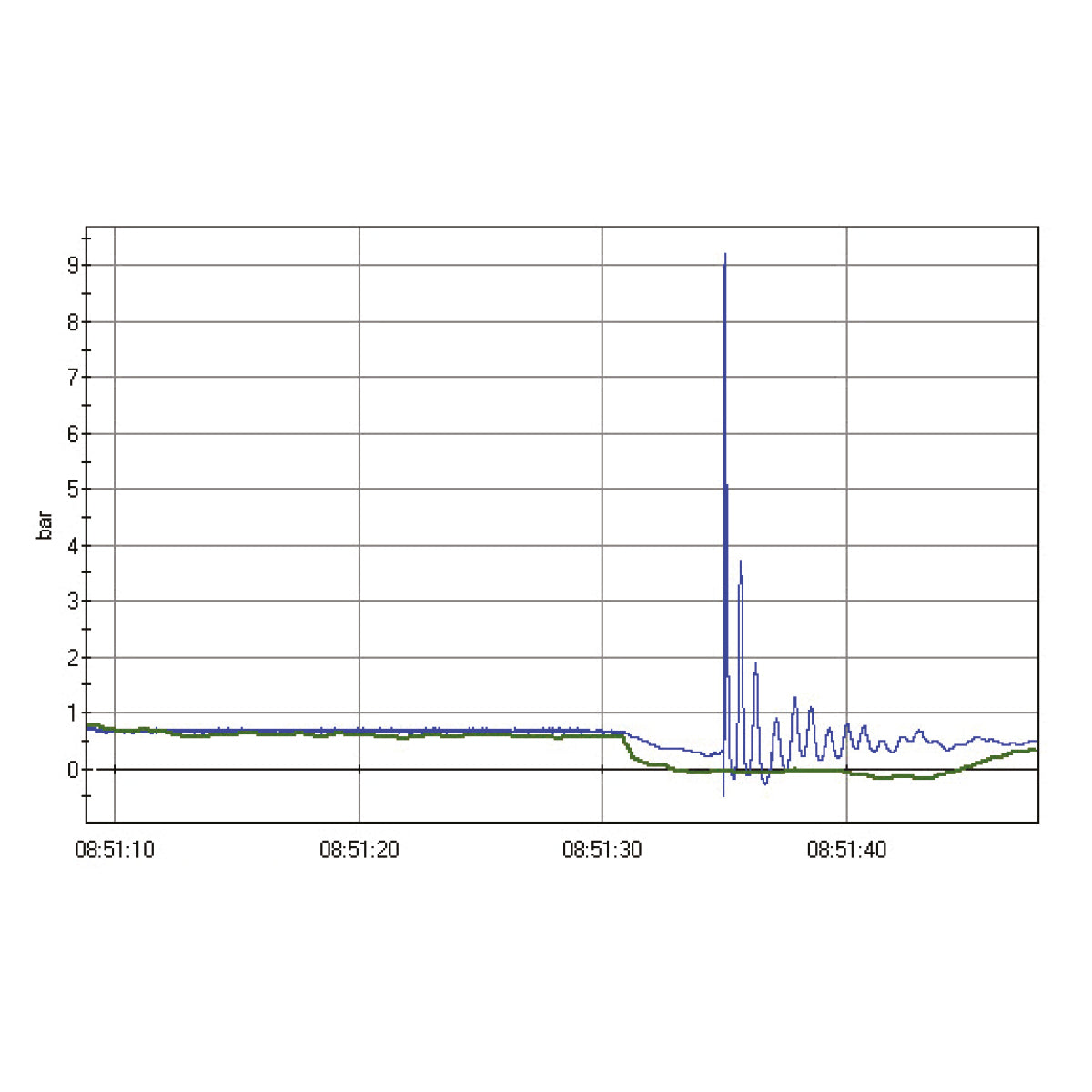

The customer had problems with pressure surges in a newly built pumping station. It was pumped with a pressure of 0.8 bar. When the pumps stopped, a negative pressure of 0.5 bar first occurred, then a pressure transient with an overpressure of 9.2 bar occurred. The whole process takes place in a fraction of a second. The pipe system is subjected to loads for which they are not intended and the sound can be compared to a car driving into a wall. Due to the fast pace, we could not guarantee that we could solve the problem with our WHP (Water Hammer Protector) valve, but we were happy to give it a try.

Solution

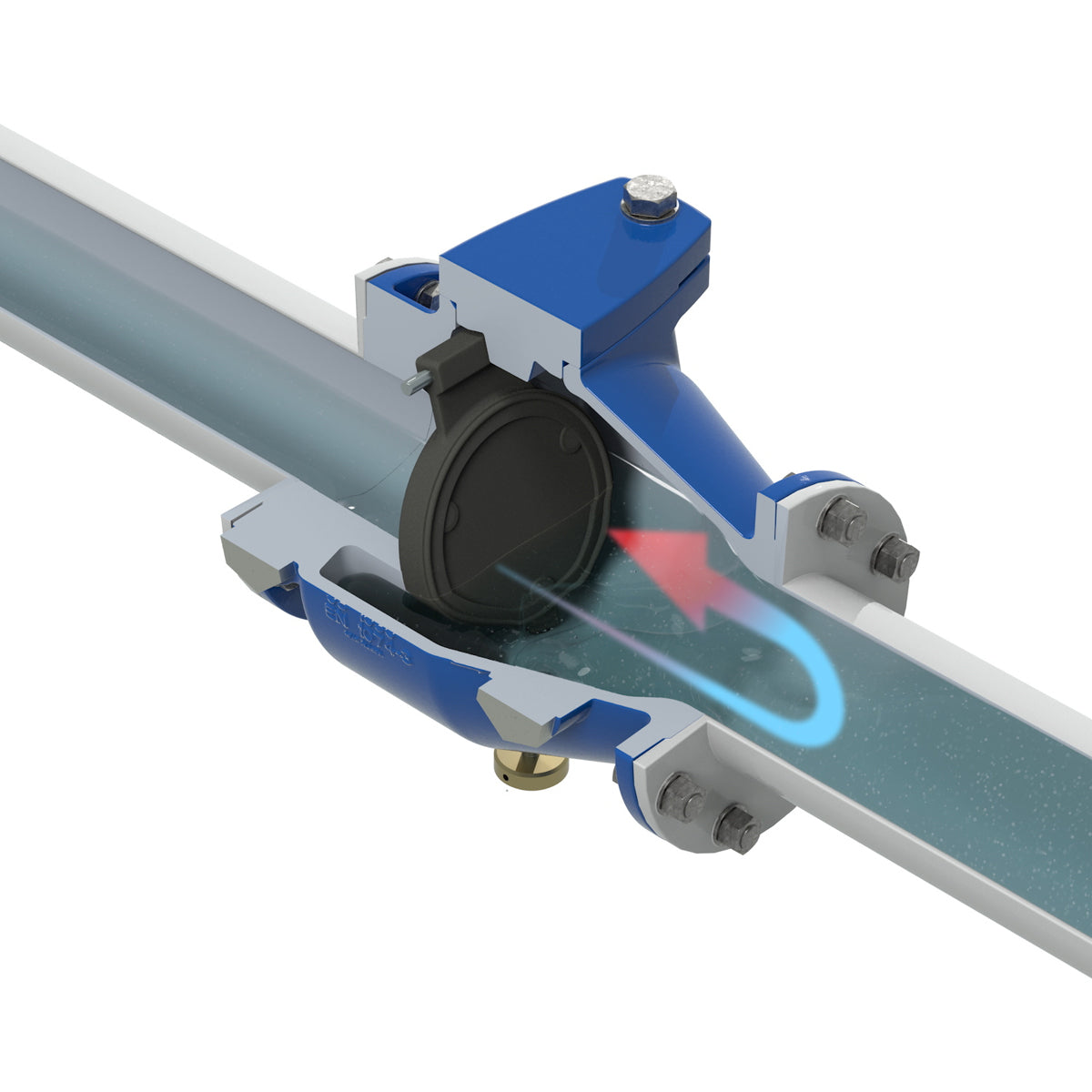

BPS's own developed pressure shock dampening check valve, WHP, dampens both the over- and under-pressure phase in one pressure stroke. When the pump stops and the fluid column's kinetic energy wants to continue, negative pressure occurs. The vacuum valve then lets in air which reduces the negative pressure and dampens the overpressure in the overpressure phase. With the help of a bypass on the valve, the media will also be released past the flap when the pressure increases.

Results

We made a measurement both before and after installation of the WHP valve. The diagram right here shows a clear result. BPS's proprietary WHP solved the problem and the pressure strokes were completely dampened in this case.

An installation of a WHP non-return valve can reduce pressure surges that risk causing major and costly damage to pipe systems, pumps and valves.

Blue curve shows pressure strokes with conventional check valves.

Green curve shows results with WHP 6503 installed.