Flow measurement on the drinking water network

Use this text to share information about your brand with your customers.

Describe a product, share announcements, or welcome customers to your store.

Background & challenges

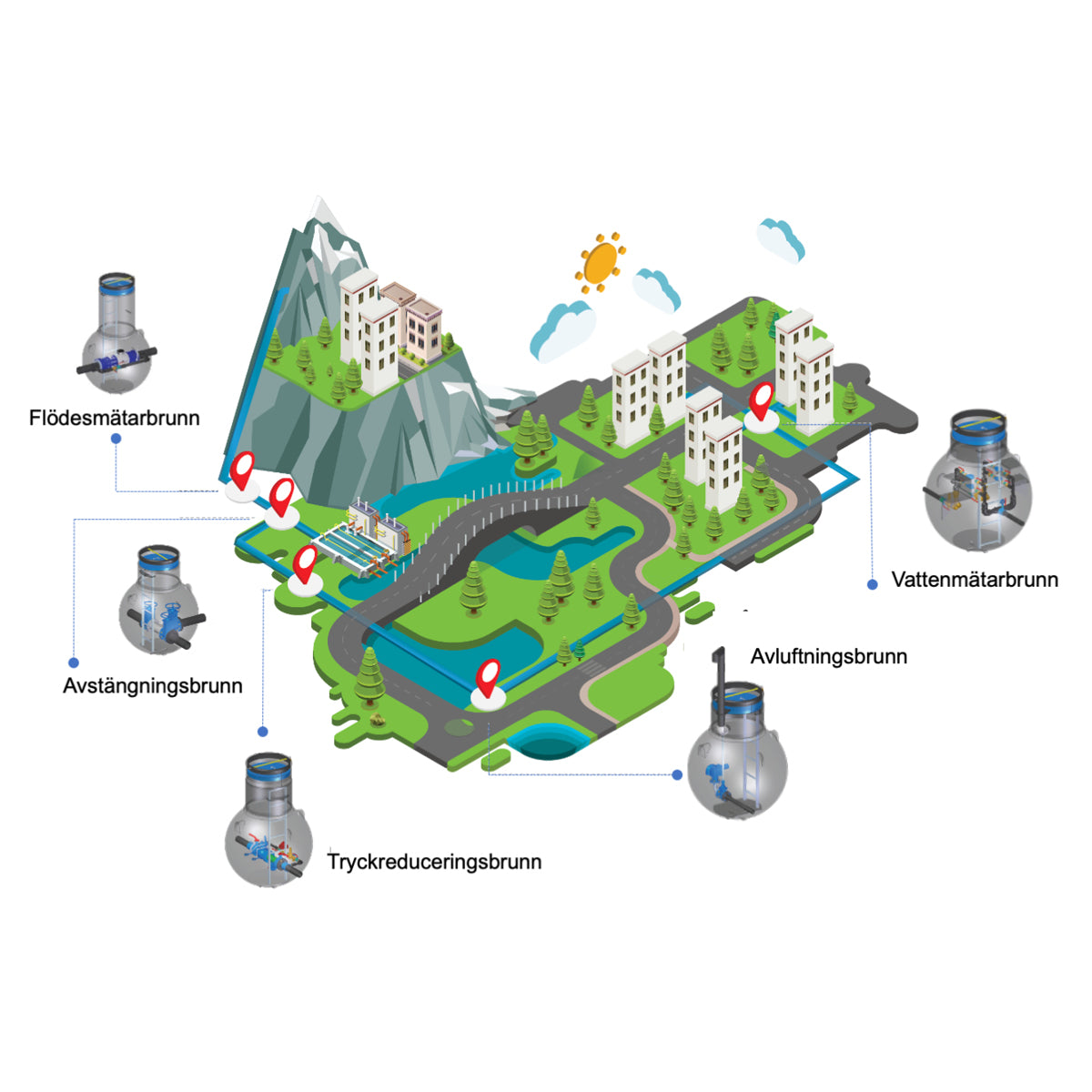

Placing flow meters at strategic points in the pipeline network has historically involved a number of challenges, such as access to electricity and installation costs. Functions that are sought in addition to flow measurement can also be pressure measurement or pipe burst function.

Solution and result

Based on these challenges, we at BPS decided to develop a solution that significantly simplifies flow measurement on the drinking water network. Functions in addition to flow measurement that we sought were also the possibility of pressure measurement and/or pipe burst function. In addition, variants of own power supply for example via turbine or with battery operation.

This means that it has now become relatively easy to place flow meters at strategic points in the pipeline network.

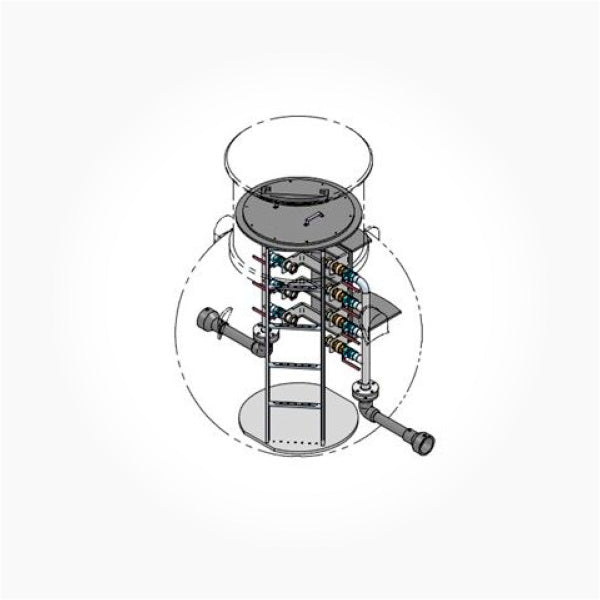

Our solutions for wells

Show allFilled lines reduce costs and increase operational reliability

Use this text to share information about your brand with your customers.

Describe a product, share announcements, or welcome customers to your store.

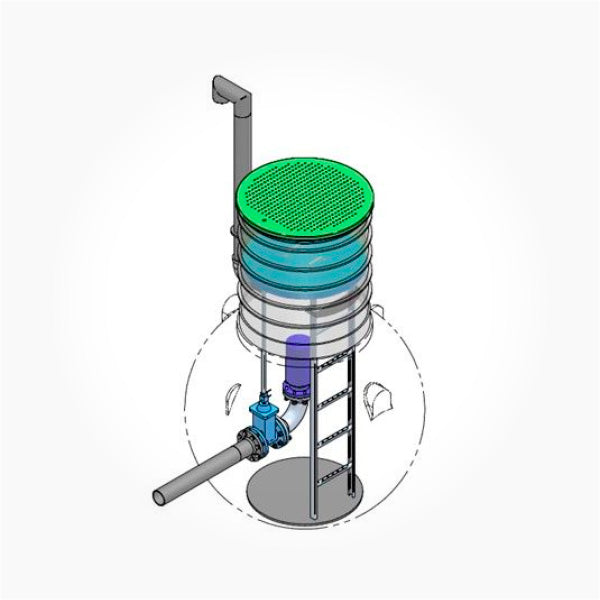

Background & challenges

When the trailing point of a line is lower than the highest point in the system, siphon is created and the line runs the risk of emptying when the pump stops. Because air then enters the system, unwanted pressure surges often occur during subsequent pump starts.

Solution and result

To counteract this, we at BPS have developed various solutions to the problem. An example is a balanced system that retains the liquid column in the pipe system and that does not require an electrical connection. The entire system is supplied in a polyethylene downspout.

With BPS's unique solution, you now avoid the risk of draining lines and troublesome pressure surges, thereby increasing operational reliability. The placement works, with this solution, even in areas where electric traction would be difficult to defend financially.

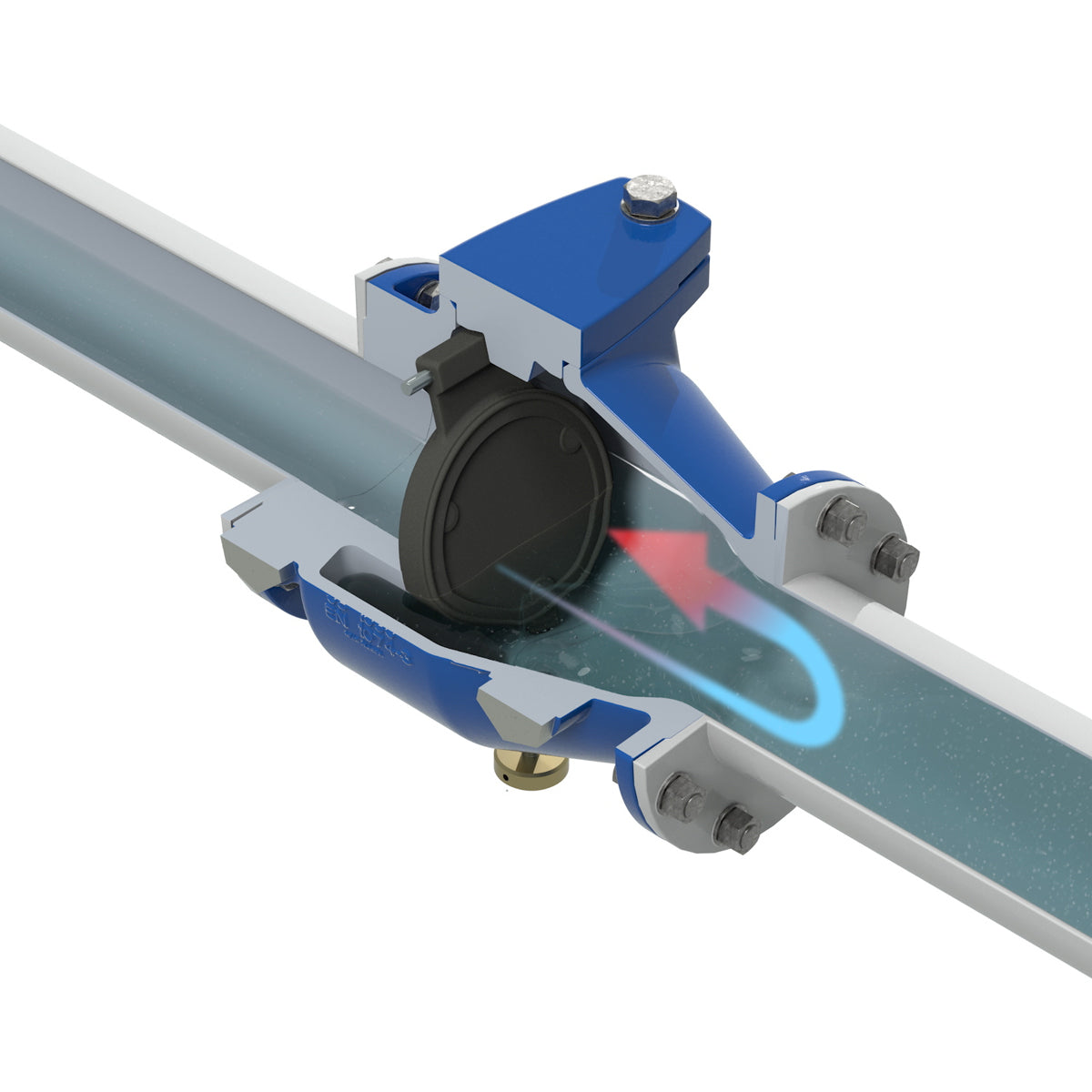

WHP - a pressure shock dampening check valve

Use this text to share information about your brand with your customers.

Describe a product, share announcements, or welcome customers to your store.

Background & challenges

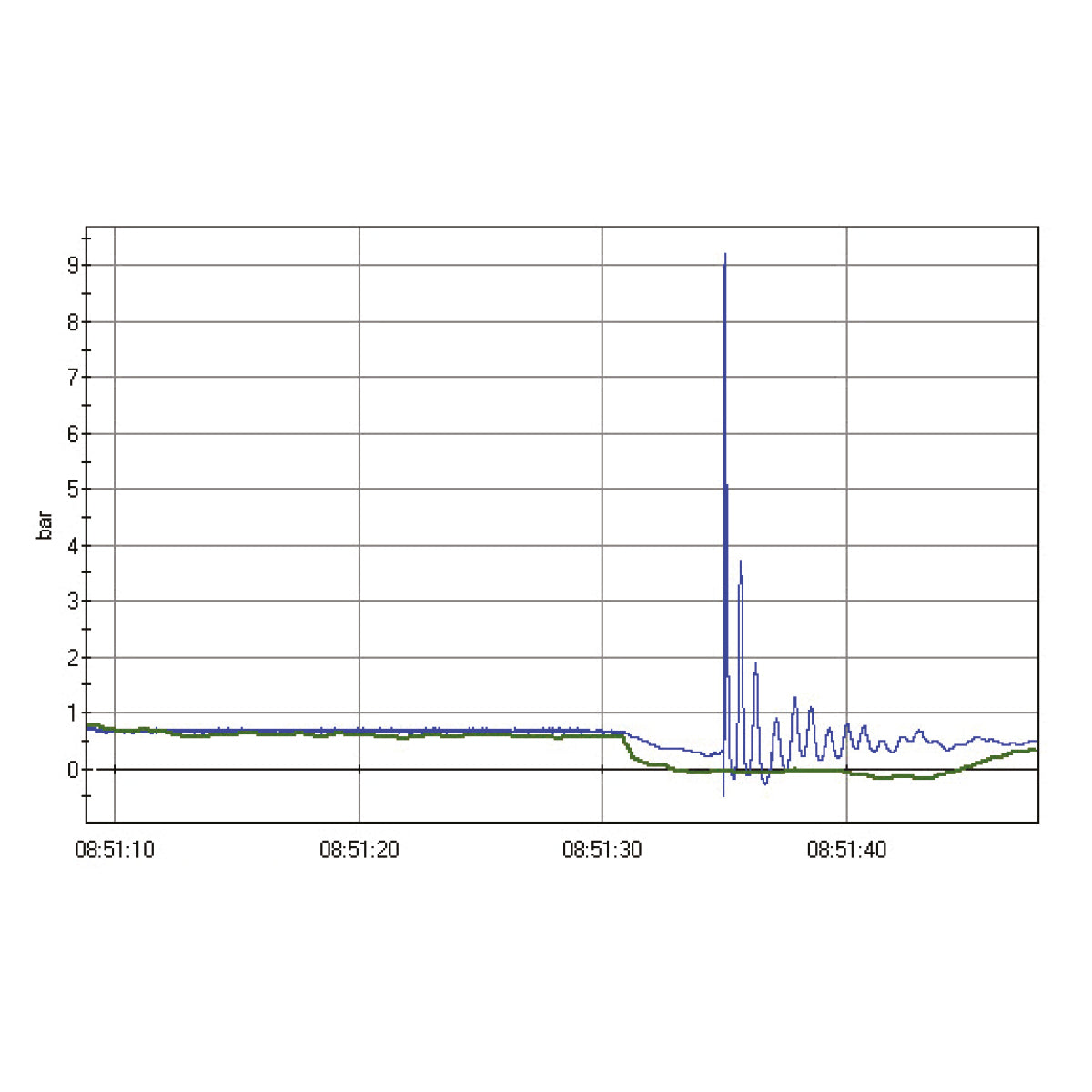

The customer had problems with pressure surges in a newly built pumping station. It was pumped with a pressure of 0.8 bar. When the pumps stopped, a negative pressure of 0.5 bar first occurred, then a pressure transient with an overpressure of 9.2 bar occurred. The whole process takes place in a fraction of a second. The pipe system is subjected to loads for which they are not intended and the sound can be compared to a car driving into a wall. Due to the fast pace, we could not guarantee that we could solve the problem with our WHP (Water Hammer Protector) valve, but we were happy to give it a try.

Solution

BPS's own developed pressure shock dampening check valve, WHP, dampens both the over- and under-pressure phase in one pressure stroke. When the pump stops and the fluid column's kinetic energy wants to continue, negative pressure occurs. The vacuum valve then lets in air which reduces the negative pressure and dampens the overpressure in the overpressure phase. With the help of a bypass on the valve, the media will also be released past the flap when the pressure increases.

Results

We made a measurement both before and after installation of the WHP valve. The diagram right here shows a clear result. BPS's proprietary WHP solved the problem and the pressure strokes were completely dampened in this case.

An installation of a WHP non-return valve can reduce pressure surges that risk causing major and costly damage to pipe systems, pumps and valves.

Blue curve shows pressure strokes with conventional check valves.

Green curve shows results with WHP 6503 installed.

Flap check valve ductile iron (WHP), flanged

To productDelivery of valves for level regulation

Use this text to share information about your brand with your customers.

Describe a product, share announcements, or welcome customers to your store.

Background & challenges

A municipality needed a level regulation of two communicating water towers with different heights. A system that ensures operation but also provides the possibility to smoothly close the system in the event of, for example, a burglar alarm or other unforeseen situation.

Solution

Based on different scenarios, BPS developed proposals according to the following examples:

If one were to run the large reservoir as number one and supplement it with electrically controlled valves on both lines. Then, when desired, these valves can be remotely controlled so that the reservoir is "disconnected".

This would then be done, for example, at a high level. When this is disconnected, the smaller reservoir enters and supplies the network with water. The smaller reservoir, in turn, is equipped with a Hydrobloc type leveling valve. This valve maintains a preset level of +/- a few centimeters. The hydrobloc valve is equipped with a remote shut-off so that, when the large reservoir is disconnected, the inlet to the smaller reservoir is also closed.

In that case, this would mean that you would also get turnover on the water in the smaller reservoir. In addition, a bypass had to be built so that the water that leaves the smaller reservoir goes this way via a non-return valve.

Results

Based on the above, the final solution consisted of a number of double eccentric butterfly valves with electric actuators for regulation.

The valves can also be emergency closed if necessary, e.g. the intruder alarm to the reservoir goes off.

Other maintenance benefits

This smart BPS system would also lead to the retirement of parts of existing equipment, further reducing operational disruptions and maintenance costs.

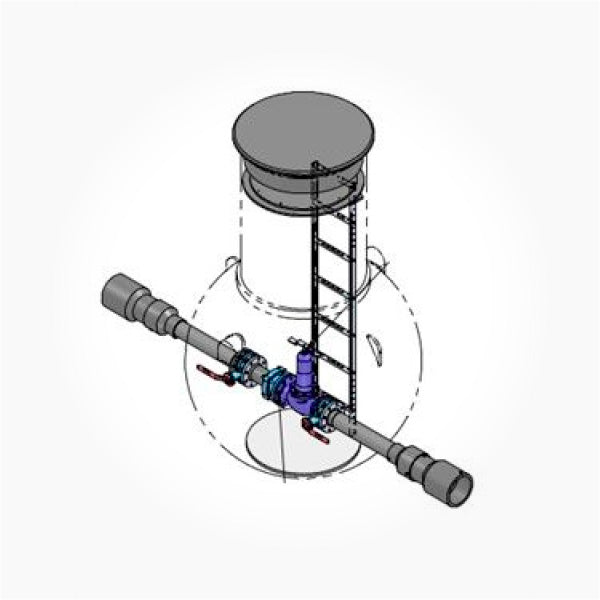

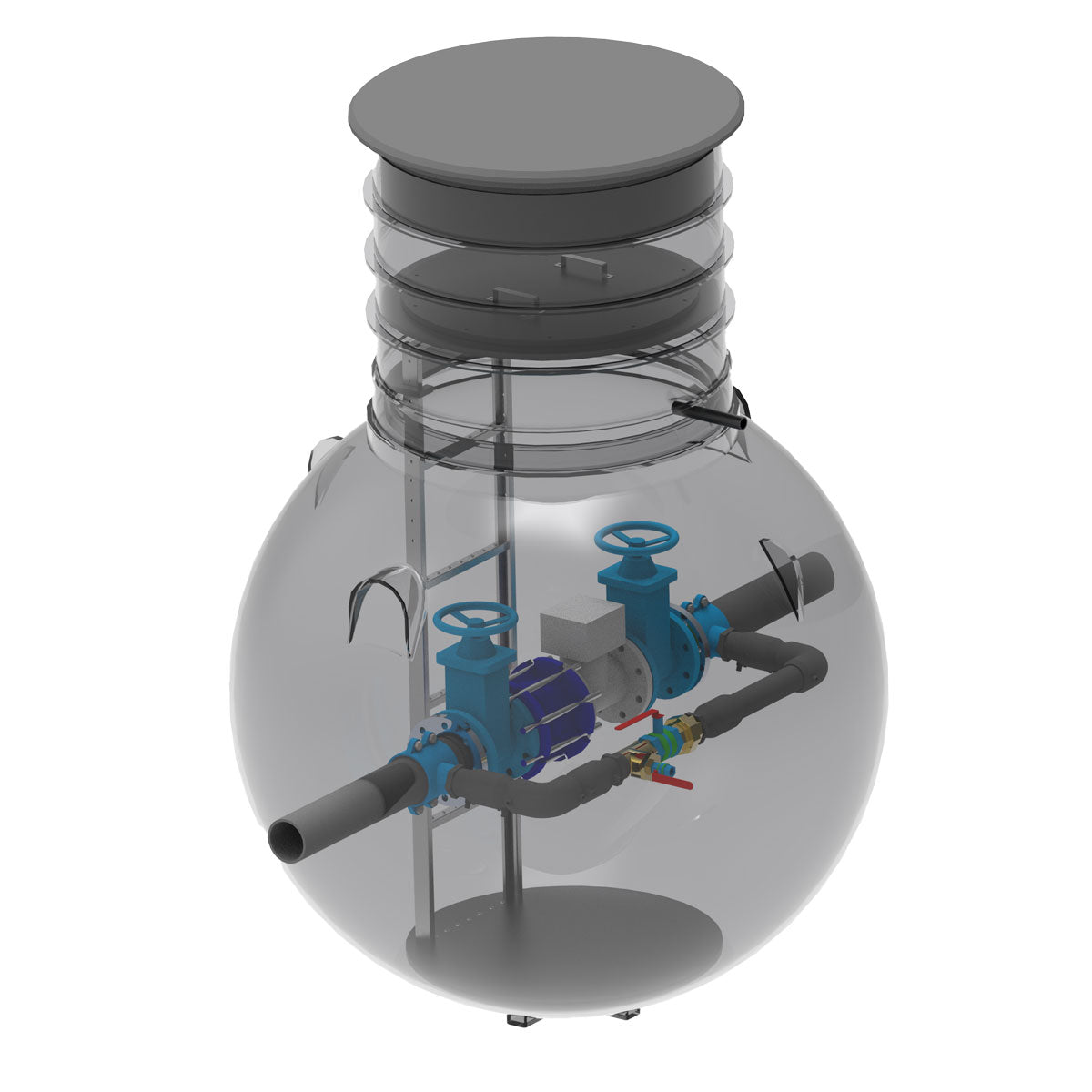

Pressure reduction reduces water losses and the number of pipe breaks

A not entirely uncommon problem in the pipeline network is "high pressure" and the significant variation of pressure between night and day. Something that can lead to losses of drinking water and a shorter lifespan of the pipe systems.

Solution

When we at BPS occasionally received these problems described by our customers, we outlined various possible solutions for this.

In practice, reducing the water pressure means that, in addition to lowering the pressure from a higher to a lower level, you also smooth out pressure variations between day and night. A pressure reduction of 1 bar could mean greatly reduced losses of drinking water and that the service life of the pipe system increased.

In order to achieve good results and be able to reduce the pressure throughout the day with varied flows, careful dimensioning and planning is required.

With this overall, we developed a model for pressure reduction stations that could be adapted to various described and occurring needs.

Results

Now our various customers can get customized pressure reduction stations, customized to fit each unique need.

Economic and environmental benefits

In recent years, BPS has successfully delivered these unique solutions to both municipalities and companies, and we can happily state that with this we have contributed to greatly reduced losses of drinking water for our customers.

In addition, the fact that the service life of the pipe system increases, which means a reduction in the number of pipe breaks, which has a long-term and positive effect on the environment and the economy.